Recognizing Membrane Bioreactors: The Future of Wastewater Treatment

Membrane layer bioreactors (MBRs) represent a notable innovation in the area of wastewater treatment, integrating biological procedures with advanced membrane filtering to improve effluent high quality. As worldwide water deficiency and stringent governing frameworks become increasingly pushing concerns, MBR modern technology offers an effective reaction via its capacity to reduce impact and optimize resource recovery.

What Are Membrane Layer Bioreactors?

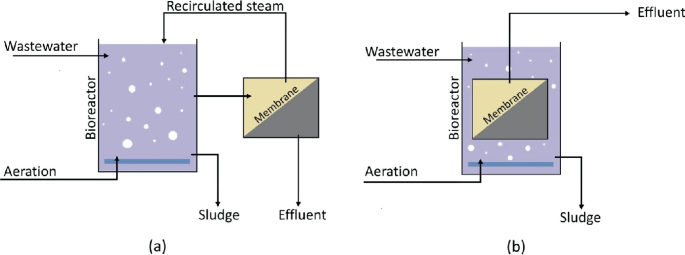

The core components of MBR systems include a bioreactor where microbial activity takes place and a membrane layer system that filterings system the blended alcohol. This double functionality makes it possible for the simultaneous deterioration of natural issue and solid-liquid splitting up in a solitary step. MBRs can operate in both submerged and exterior configurations, with submerged systems being extra common due to their compact layout and operational performance.

The adoption of MBR modern technology has actually acquired grip in numerous applications, ranging from community wastewater treatment to commercial effluent administration. MBRs are especially advantageous in circumstances where area is limited or strict effluent top quality requirements need to be satisfied. By keeping a high focus of bacteria within the bioreactor, MBRs boost the degradation of organic toxins, therefore yielding greater therapy performances contrasted to traditional approaches.

Secret Benefits of MBR Modern Technology

The combination of organic treatment with membrane filtration in MBR systems provides various advantages that set it apart from traditional wastewater treatment methods. One of the key advantages is the improved effluent top quality. MBRs effectively remove put on hold solids and microorganisms, achieving higher degrees of filtration that satisfy rigorous discharge requirements and promote water reuse applications.

One more significant advantage is the minimized sludge production. MBR systems create much less excess sludge, bring about lower disposal prices and a decline in environmental effect. The closed nature of the membrane layer system minimizes the risk of odor exhausts and improves general procedure control.

Finally, MBRs are functional and versatile, making them appropriate for numerous wastewater types, consisting of commercial and municipal sources. The capability to incorporate with sophisticated therapy modern technologies further boosts their effectiveness, making MBRs an appealing remedy for the future of wastewater management.

Obstacles and Limitations of MBRs

While MBR technology supplies various advantages, it also faces several obstacles and restrictions that can impact its widespread adoption. One substantial challenge is the high capital and functional prices related to MBR systems. The preliminary financial investment for membrane products and the required facilities can be substantial, making it much less accessible for smaller industries or municipalities.

Furthermore, membrane fouling remains a critical concern that can reduce system performance and boost upkeep needs. Fouling occurs when solids, raw material, or microorganisms accumulate on the membrane surface, causing decreased permeability and needing frequent cleaning or substitute.

One more constraint involves the intricacy of the technology. MBR systems call for experienced workers for operation and upkeep, which can be a barrier in areas with restricted technological know-how. The disposal of invested membrane layers provides environmental issues, as the materials are commonly not eco-friendly and can add to throw away management challenges.

Finally, while MBRs can successfully treat a wide variety of wastewater, they may not be appropriate for all applications, specifically those with high concentrations of fats, oils, and greases, demanding additional research study and advancement to resolve these constraints.

Applications of Membrane Layer Bioreactors

In numerous markets, membrane layer bioreactors (MBRs) have actually emerged as a flexible option for wastewater therapy (Membrane Bioreactor). Their applications extend community, commercial, and farming setups, showcasing their versatility and efficiency in varied atmospheres. In local wastewater treatment plants, MBRs considerably boost effluent top quality, enabling water reuse and decreasing the ecological effect of released wastewater

Industrially, MBRs are employed in food and beverage processing, textile production, and pharmaceutical manufacturing, where they efficiently deal with high-strength waste streams. Their capacity to take care of varying and rising and fall tons pollutant focus makes them specifically beneficial in these sectors. Additionally, MBRs promote the elimination of microorganisms, put on hold solids, and raw material, adding to compliance with stringent discharge regulations.

In farming, MBRs are progressively used for dealing with farming drainage and animals wastewater, allowing the recovery of nutrients for fertilizer production. They also aid in the therapy of greywater for watering, promoting lasting water management methods.

The flexibility of MBRs is further shown by their combination with other technologies, such as anaerobic food digestion and progressed oxidation processes, enhancing total efficiency and resource healing in wastewater treatment systems.

The Future of Wastewater Therapy

Improvements in innovation and a growing emphasis on sustainability are shaping the future of wastewater therapy. Membrane layer continue reading this bioreactors (MBRs) exhibit this shift by integrating biological therapy processes with membrane purification, leading to high-quality effluent suitable for reuse. The pattern in the direction of round economies is motivating facilities to adopt MBRs for their capacity to recuperate resources, such as water and nutrients, from wastewater.

Developments in membrane products and setup are improving the performance and long life of MBR systems, minimizing functional prices and energy intake. Smart modern technology assimilation, consisting of real-time tracking and automated control systems, is more enhancing efficiency and making it possible for predictive maintenance, therefore decreasing downtime.

In addition, societal assumptions and regulative stress are pushing districts and sectors to take on even more lasting Recommended Reading practices. Membrane Bioreactor. The change towards decentralized wastewater therapy remedies is getting traction, permitting localized therapy that lowers transportation expenses and energy usage

Verdict

Membrane layer bioreactors (MBRs) represent a transformative method to wastewater treatment, integrating biological processes with advanced membrane innovation. The benefits of MBRs, including boosted effluent high quality, lowered spatial needs, and reduced sludge production, place them as a viable option in the middle of growing urbanization and stricter ecological policies. Regardless of existing challenges, the ongoing development in membrane materials and operational methods assures to reinforce the efficiency and adoption of MBRs, ensuring their essential function in the future of lasting wastewater monitoring.

Membrane layer bioreactors (MBRs) represent a significant development in the area of wastewater therapy, incorporating biological procedures with innovative membrane layer filtering to boost effluent top quality.Membrane layer bioreactors (MBRs) integrate biological treatment processes with membrane purification to efficiently treat wastewater.The combination of biological therapy with membrane layer purification in MBR systems uses many advantages that set it apart from typical wastewater treatment techniques. Membrane bioreactors (MBRs) exemplify this shift by incorporating organic treatment processes with membrane layer purification, resulting in high-quality effluent suitable for reuse.Membrane layer bioreactors (MBRs) represent a anonymous transformative approach to wastewater treatment, integrating organic processes with innovative membrane modern technology.